- Home

- Education & Support

- Frequently Asked Questions

- Pentair WellMate FAQs

Got a question? Chances are we’ve heard it before. For your convenience, we’ve assembled answers to the most commonly asked questions regarding WellMate Solutions and services. If you don’t see the answer to your question below, be sure to contact our customer service.

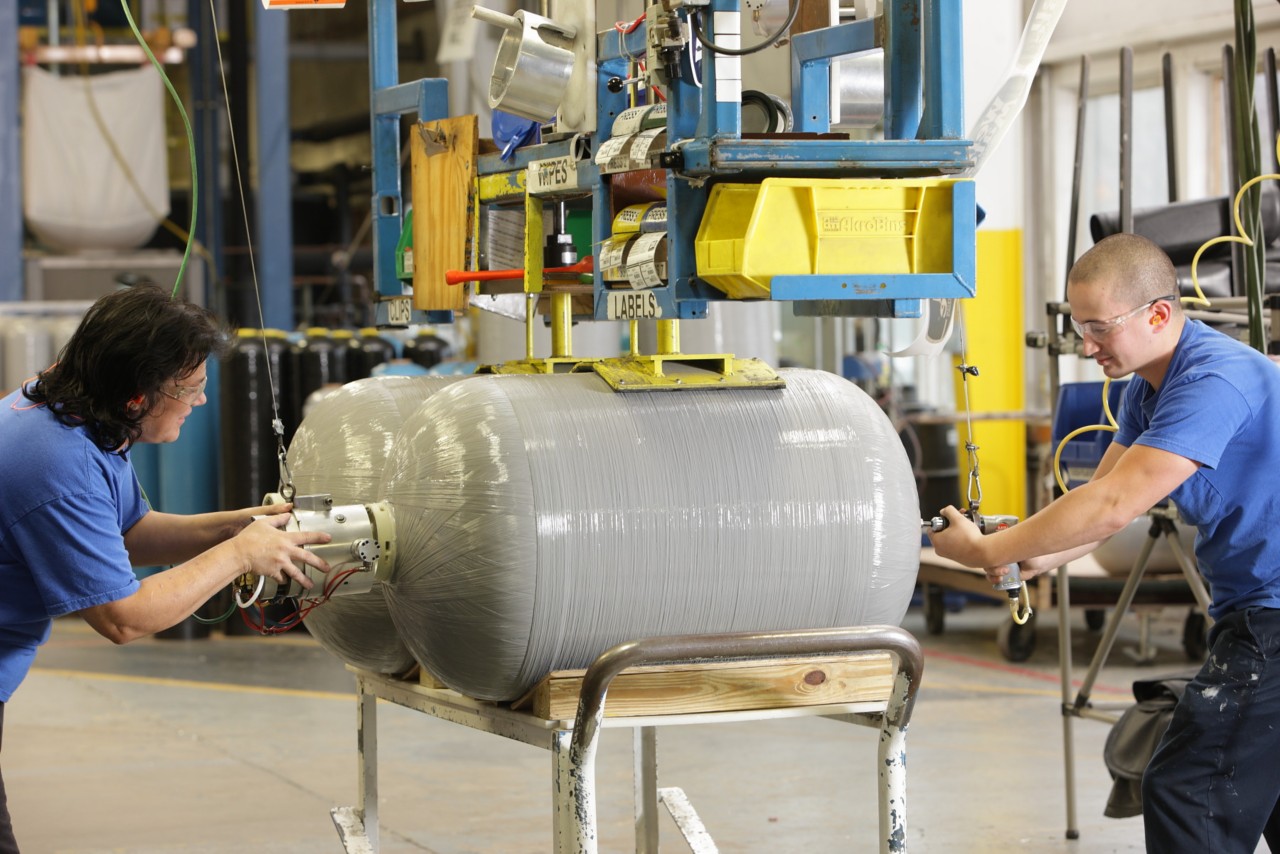

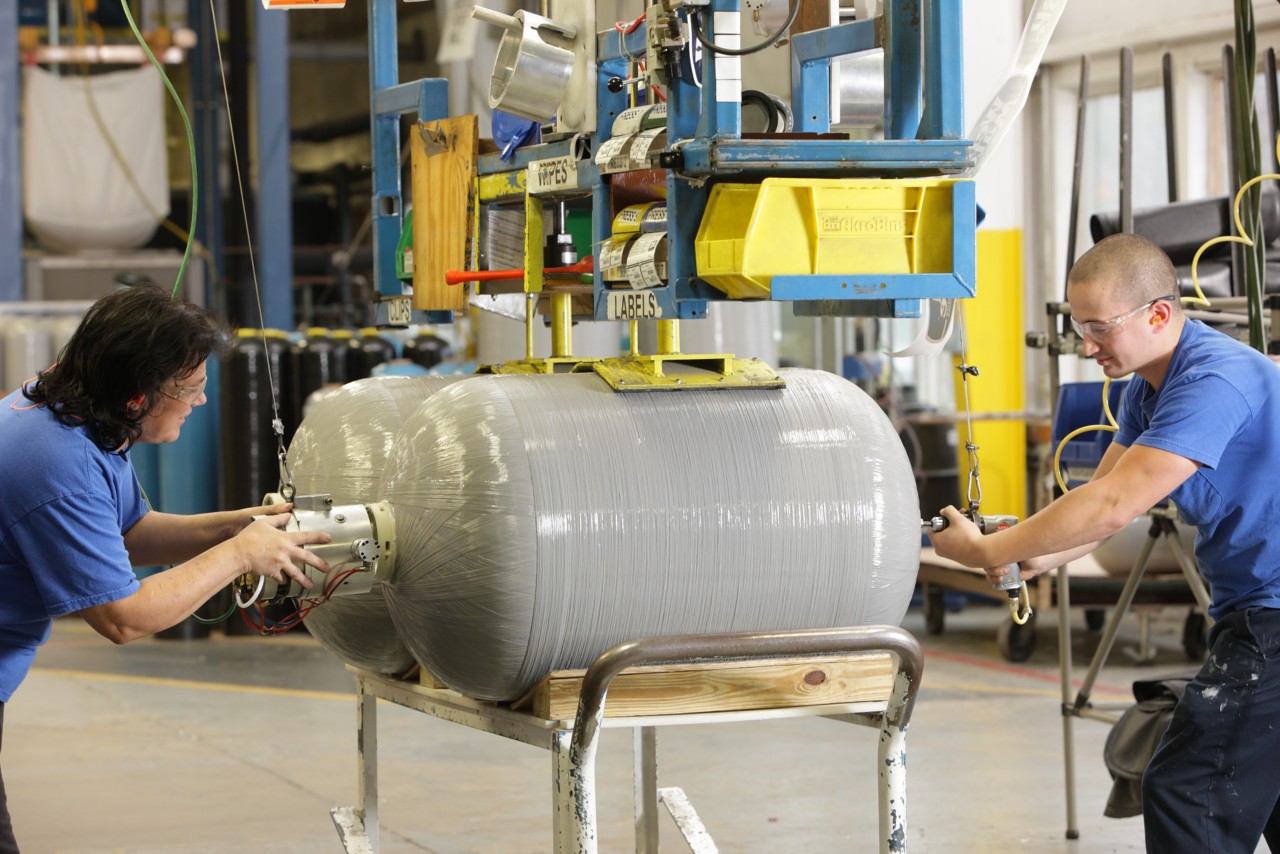

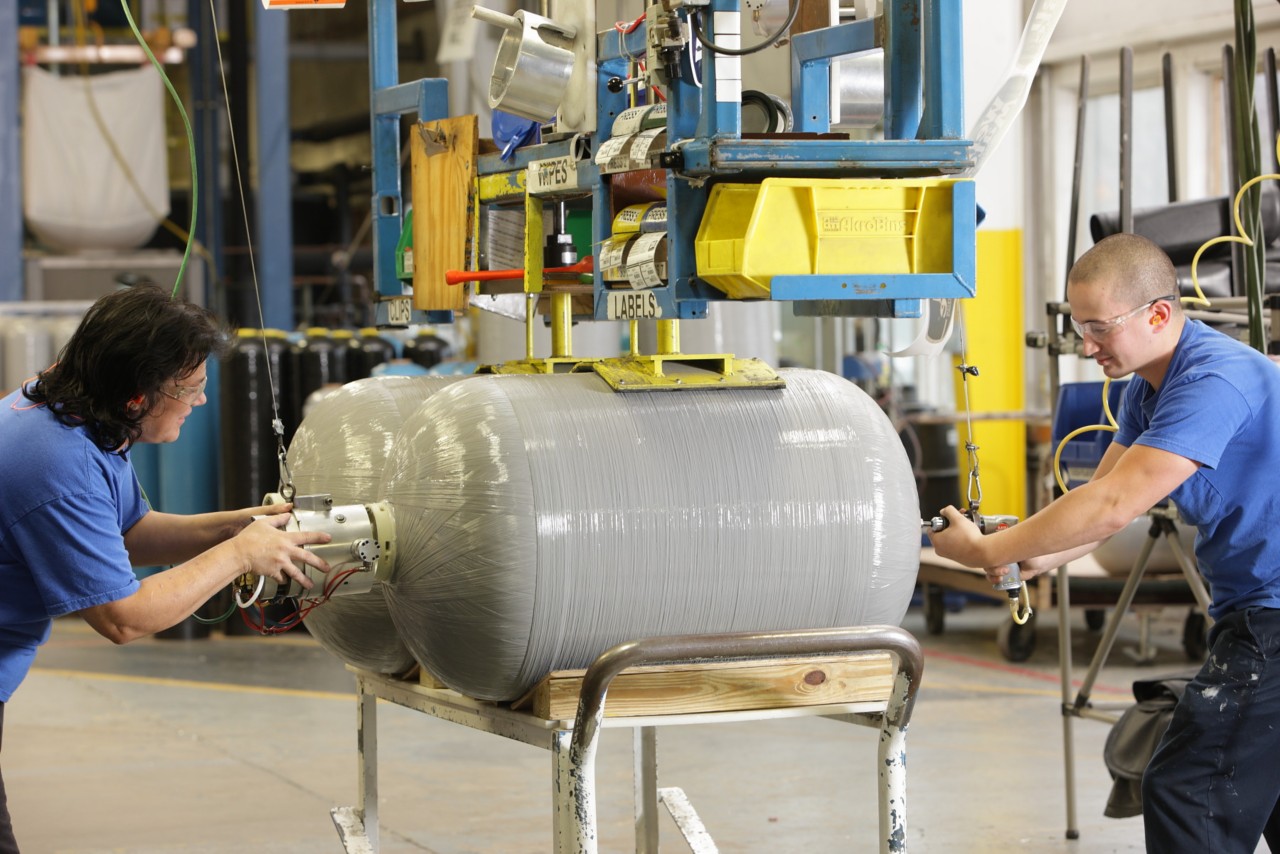

Q. What is the construction of our pressure vessels?

A. The vessels have a polyethylene liner with a winding on the outside of continuous strand fiberglass and Epoxy Resin.

Q. How does a person size the WellMate pressure tank?

A. The pressure tank is sized by the flow capabilities of the well pump.

Q. What is the proper way to install the WellMate pressure tank?

A. To install a WellMate pressure tank, the system should include at least one union for service, tank tee, gauge, check valve, pressure relief valve, drain valve, pressure switch, and a valve to isolate the service line from the pressure tank.

Q. How do you check the air cell pressure?

A. To check the pressure in the air cell, the power supply to the well pump must be turned off and the water must be drained from the pressure tank.. With the pump turned off and the water drained from the pressure tank a standard tire gauge can be used on the valve stem at the top of the tank. The pressure in the air cell should be 4 psi lower than the pump cut-in pressure.

Q. What are the operating parameters of the WellMate pressure tanks?

A. The maximum external temp. is 120 deg. F. the maximum internal temp. is 100 deg. F. the minimum operating temp. is 40 deg. F. The maximum allowable vacuum is 5 inches of mercury. Operating pressure varies with the size and application.

Q. Can the air cell be replaced in the WellMate pressure tank?

A. The air cell can be replaced, but the pressure tank must be removed from the system and disassembled. Instructions will come with new air cell. (Installation kit)

Q. Can the UT and the HP series pressure tanks be used with chlorine?

A. The chlorine will have no effect on the polyethylene inner liner of the pressure tank.

Q. What is an air volume control and what does it do?

A. The air volume control is used to convert the UT series pressure tank into the HP (hydopneumatic) series pressure tank. When the AVC is installed it will control the volume of air that is in the pressure tank.

Q. What is a micronizer and what does it do?

A. The micronizer is used to inject air into the stream of water coming from the well. It is usually adjusted to inject air 30 to 50 per cent of the overall pump time. Adjustments are made by turning the knob on the side of the unit. The dial can be turned left or right to achieve the same results.

Q. Can the HP series pressure tank be used to remove odors from the well water?

A. When the HP pressure tank is used with the micronizer it will help remove odors from the well water. The air injection allow (aeration) of the water which will allow the odors to dissipate and be allowed to escape out through the ¼” barbed fitting at the top of the pressure tank. A ¼” hose (hooked onto the barbed fitting) will allow the gases to be discharged to a safe location.